Camlock Distribution Panel Basics: Extend the Life of Your Cables

Excessive wear and tear on your cables can be a headache. The good news is that we have a simple solution using camlock distribution panels to help you extend the life of your cables. If you’ve ever noticed that the connections between the inline camlocks on your cables and the connectors on your Camlock Panel look tense and strained, you're likely using the wrong angle of panel mounts. Camlocks need proper alignment to have secure connections that will distribute power efficiently throughout your portable power system. Choosing the wrong angle of panel mounts for your camlock distribution panel puts unwanted stress on your connections and can lead to failure over time.

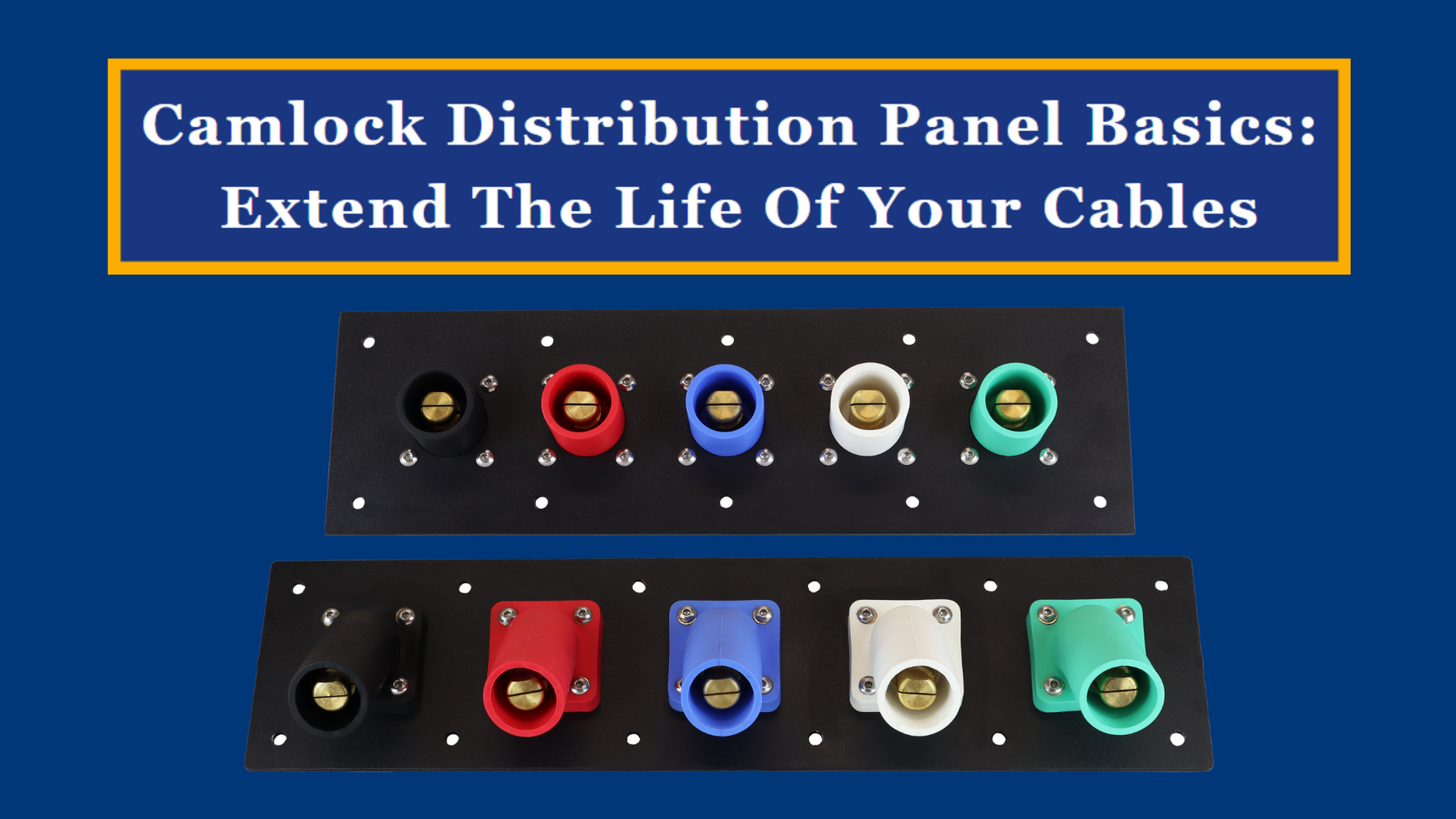

Selecting the best camlock angle for each application is a fool-proof way to avoid wasting time and money by constantly replacing worn out cables. Using the proper angle will let you easily connect your cables, optimize space, and relieve harmful strain. There are two main angle variations for camlock panels, 45 degrees and 90 degrees. 45° Camlock connectors are often referred to as “angled”, while 90° connectors are referred to as “straight”.

Defining Camlock Distribution Panels

In a portable power system, camlock panels work similarly to a power outlet/inlet. Usually female panel mount camlocks indicate the outlet is hot, whereas male panel mount cams usually indicate power is being brought into the unit, similar to an inlet. The panel serves as a connection point to distribute electricity throughout the power system. We offer dozens of camlock panel variations on our website, with customizable configurations available. Each of our camlock distribution panels features a unique, high-density configuration that allows for more connections per square foot.

Our pre-assembled panels are diligently tested by the manufacturer to make sure that they’re free from defects and ready to be installed. The camlocks quickly connect and lock into place, making them excellent for you to use while connecting a generator. Camlock panels are also used in our portable power enclosures, such as our Camlock Connection Boxes. They offer a convenient, organized way to connect power distribution units within a portable power system for long-term electrical distribution.

Panel mounts are the individual components in a camlock panel that determine the angle of the cable’s connection. Series 16 panel mounts are commonly used because of their ability to withstand up to 400 amps of electrical current per device! The panel mount camlocks are typically organized into color-coded rows on a panel, indicating the proper voltage that each row is rated for. For example, a camlock panel that contains black, red, white, and green panel mounts should be rated for 240 volts. Adding rows of panel mounts to a camlock panel will increase its maximum ampacity rating by 400 amps for each Series 16 row.

We offer individual camlock connectors on our website so that it’s easy for you to swap out older cams and make your camlock panel function as if it were brand new! Our operations team works hard to keep our inventory fully stocked so that you can enjoy same-day shipping with expedited options available.

Choosing the Correct Camlock Distribution Panel

We love the Power Assemblies Type W Generator Extension Cables because of the premium quality materials they use to build their genset cables. However, all cables, no matter how great the quality, are still subject to accumulating damage over time. Connecting your cords to panel mount camlocks with a suitable angle can help to preserve the connection.

Camlock panels with 90° panel mounts are a good match for camlock panels mounted on the bottom of an enclosure. The straight angle allows you to comfortably connect your cables and let them hang naturally without becoming strained, making it ideal for areas that are tight on space.

45° camlock panels pair perfectly with camlock panels that you need to mount on the side of an enclosure. The angle allows the cable to lock into place easier, whereas installing a cable on a 90° side mounted panel may be a bit tougher to connect on the side. This is especially true the higher your panel is mounted because 4/0 cables weigh approximately 1lb per foot making that much more difficult to connect.

A 90° side mounted panel would cause strained angles that stick out and take up space. Choosing enclosures with a 45° side mounted camlock panel will take pressure off your cables and help them to last longer.

With everything that you’ve learned in this article, you should now be prepared to choose the best camlock panel for your next project. If you’d like to see a visual comparison of the two angle variations for camlock distribution panels, watch our new YouTube video below, The Ultimate Camlock Connection Stress Test.

Please email our Portable Power Experts at PPG@ATIelectrical.com or call us directly at (800)-597-9311 if you have questions about products mentioned in this article, or if you’d like to request a free quote.

CALL OR TEXT NOW 800-597-9311

CALL OR TEXT NOW 800-597-9311

Leave a comment