Adjustable Motor Control: Why You Need a Variable Frequency Drive

For companies that depend on electrical equipment to run their businesses, any opportunity to lower utility costs, improve system efficiency, and reduce equipment maintenance will contribute significantly to the success of the business and ultimately improve its bottom line.

Believe it or not, there’s a simple device that can do all these things, and most businesses aren’t even aware of it. It’s called a variable frequency drive, or VFD.

A VFD is an adjustable motor control mechanism. It’s used in electro-mechanical systems to safely control motor speed and torque. It does this by adjusting the electrical frequency and voltage supplied to a motor. A VFD allows you to run motors and the systems they control at lower speeds, which are generally more efficient and aligned with specific business needs.

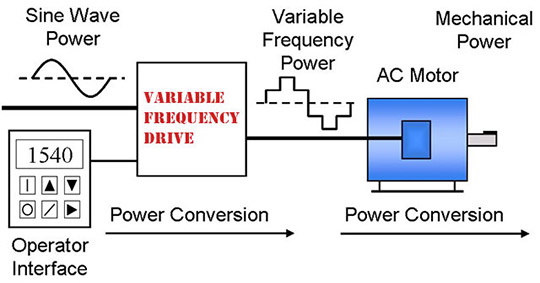

This illustration shows the key components of a VFD and how it works:

Image from Wikipedia, “Variable-Frequency Drive,” adapted and used with permission under the Creative Commons Attribution-Share Alike 3.0 Unported license.

A VFD by any other name…

A variable frequency drive may also be called:

- AC drive

- adjustable frequency drive

- adjustable speed drive

- variable speed drive

- variable frequency controller

- micro drive

- inverter drive (or inverter)

Let’s take a closer look at how a VFD can benefit your business.

Reduced energy usage and costs

In many situations, businesses don’t need motors, applications, equipment, or devices to run at the full speed level that they were manufactured to operate at. A VFD can be used to operate them at reduced speeds that meet the requirements of a particular business function. When you run equipment at a lower speed, you can cut back on waste and reduce energy usage and costs.

Did you know? Approximately 25% of the world’s electricity is used by industrial applications, yet the market penetration of VFDs is extremely low (estimates say it could be as low as 3%). This presents a big opportunity for companies to reduce electricity usage and costs. Don’t forget: VFDs can be used in new installations and retrofit into existing systems.

You might be surprised by how much you could save by using a VFD. That’s because cost savings are bigger in variable-torque centrifugal fan and pump applications compared with fixed-speed equipment.

In a variable-speed application, the load’s torque and power vary with the square and cube of the speed, respectively. A variable speed application running at 63 percent of full speed consumes only 25 percent of its full-speed power. That’s an extraordinary reduction in energy usage that can add up to big savings over time.

Did you know? Using a VFD is the only way to control the speed of an AC electric motor.

In addition to the energy savings, installing VFDs could qualify your firm for energy efficiency tax incentives, along with utility rebates from your electrical service provider. When you combine the savings, tax credits, and rebates, an investment in a VFD will pay for itself very quickly, often within six months.

Tip: Talk to your accountant and tax expert to make sure you take full advantage of energy efficiency tax credits and other incentives when you make “green” improvements to your business.

Another thing to remember: Many companies these days make it a priority to do business with environmentally conscious firms. Installing VFDs to make your business more energy-efficient can be a great selling point.

Improved processes and production levels

Most companies that use motors to do production work or move materials (on things like conveyer belts, etc.) find that it’s ineffective to run them at full speed. Workers simply can’t keep up, which can lead to production errors and accidents. Slowing motors to an optimal level will help workers get things done right and avoid on-the-job mistakes. In addition, working at less-intensive levels can reduce job-related accidents and injuries.

Dollars earned through more efficient production and processes coupled with dollars saved from fewer mistakes, accidents, and injuries will make a significant positive impact on your firm’s bottom line.

Tip: An electrical equipment company that supplies VFDs can provide advice on how to use them to run your business more effectively.

Reduced maintenance & longer equipment life

Equipment maintenance and replacement costs are a big cash drain for many companies. VFDs can help lower these by running your equipment at reduced, more efficient levels. Your equipment will last longer, will have less downtime, and require less maintenance if it’s not running at full speed all the time.

Controlling motors with a VFD will also protect them from common issues, including:

- Electro-thermal overloads

- Under-voltage

- Over-voltage

Another plus: When you start a motor or system with a VFD, it will not experience the “instant shock” that happens with a typical cold starting process. Instead, the system will ramp up smoothly, which can eliminate not just wear on the motor but also belts, gears, and bearings.

Finding the right VFD

VFDs have been around in some form for almost 100 years, and recent advances have reduced their size and cost. Performance has also improved dramatically because of improvements in semiconductor switching devices, drive topologies, simulation and control techniques, and control hardware and software.

The operator interface lets you input information to control your system, including the speed you want it to run at. The interface translates that information to the variable frequency drive or controller. The device converts the incoming sine wave power into variable frequency power that runs your motors and systems at the level you want.

VFDs are available in a number of different low- and medium-voltage AC-AC and DC-AC topologies. There are options available to run virtually any application or system.

Tip: It’s a good idea to choose a VFD with the interface built into the device. It makes it much easier to install and takes the guesswork out of whether the units are compatible.

The best way to get started with VFDs is to work with an electrical supply company that has experience with them. Simply explain the type of work you do and what you want to accomplish with a VFD, and they’ll guide you to the perfect solution.

So, what are you waiting for? Every day you wait to install a VFD is money wasted on higher energy costs, inefficient production, and unnecessary wear and tear on your equipment.

CALL OR TEXT NOW 800-597-9311

CALL OR TEXT NOW 800-597-9311

Leave a comment